Designing for 3D Printing | Blog Entry 5

/Designing objects for 3D printing is often different from designing things regularly. There are a few things that a designer would have to take into consideration and these usually involves design practices to ensure that the model you create would be 3D printable and would work without too many further modifications. These includes the way your printer print things out, details and measurements as well as material selection.

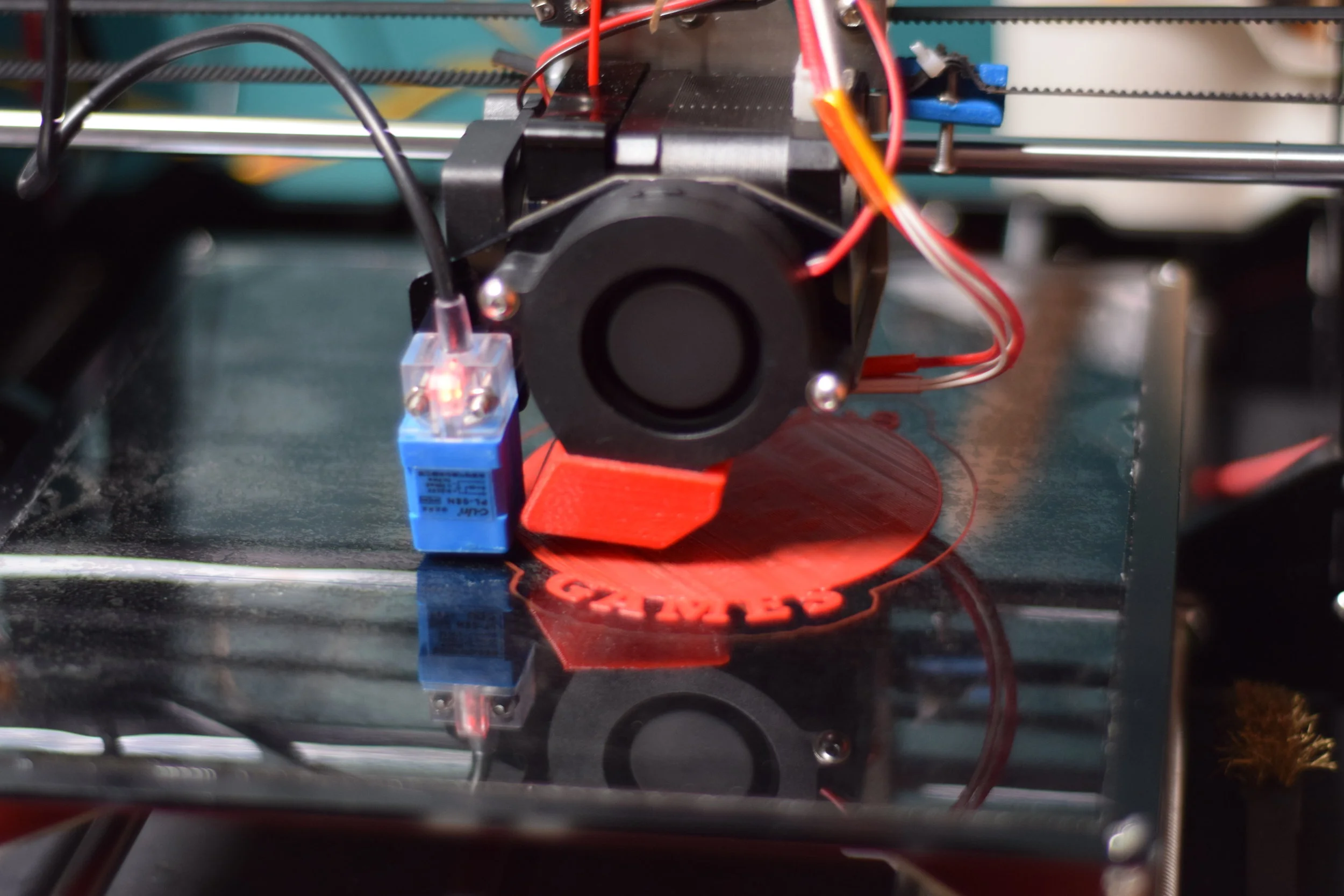

Printer mechanics

Usually with 3D printers they build up the model one layer at a time. Whether it be FDM, SLA, SLM, or other exotic methods, the process is done through consecutive layers starting from the bottom towards the top. When designing for 3D printing, one must keep this process in mind when developing their models on CAD. Certain features such as being top-heavy, curved bottoms and sharp corners and edges could impact on the success of the print itself. For example, if a model were to be printed with a moving print bed as in those found in the Prusa i3 style 3D printers a top-heavy, curved bottom object would most likely fall over during the printing process. However, where it to have a flat bottom with the centre of gravity close to the print bed, the model would most likely adhere and print fine without support. With printers that allows the object to be static while printing, the object might be able to print but with a curved (bowed) bottom, the object won't have as much contact to the build platform and may also fall over if printed without supports. Thus to maximise the success rate of a print, one must take into account how the printer operates and designs their model accordingly.

Details and measurements

When it comes to detail, there small details that may be difficult for a printer to recreate. Using an architecture model of a house, a model with a wall that's 5mm thick can print well on a printer equiped with a 0.4mm nozzle. However, a wall that's 0.3mm thick (imagine scaling things down) will unlikely print with a printer equiped with a 0.4mm nozzle. Details like sharp edges, small letters and shapes may not be as defined on some printers so it may be good to test out your printers first to see if it can achieve the detail you want. Also something to take note: more detail usually requires more time. So also it may be worth seeing how much time extra is taken for the detail that you want. A printer with a 0.3mm nozzle will give you features that are sharper and more defined compared to a 0.4mm nozzle but will take more time than otherwise. Something to consider carefully if you have a workflow going on and want to know how much time can actually take to print something out.

It's also important to note that other technologies are more accurate than others. SLA for example can print things out in much higher detail without the fuss of adjusting nozzle sizes. Ultra high end printers such as the Stratasys machines utilise a completely different technology which can accurately print things at incredibly high detail (at 16 microns on a Stratasys Objet 260 Connex for example) without loss of fidelity and the ability to print really intricate designs

Size and volume

Size and volume of your printer definitely impacts on what you can or cannot print. Obviously, a model that has a dimension of 20cm by 20cm by 20cm will not fit inside a printer with a print volume of 15cm by 15cm by 15cm. This gives designers an interesting problem of how to create something despite size constraints. One way to get around this is to have a printer with a bigger print volume. But printers with large capacities are often very expensive and might not be accessible to many people. Therefore at times, designers must get inventive and break larger models into sections which can fit in the build volume of their printers. Usually this is the preferred method as it is simple to glue parts together to form one big object or to design fasteners or connectors in the design such that those printed parts can be assembled after printing. It definitely is good to take note on the printer build size as it may affect your overall design..

There are definitely more aspects to designing for 3D printing and most really do have to experience this to get a good understanding of what can work and what can't. Often these details are overlooked at when designing a product, prototype or a part but it certainly is good to keep in mind so when it comes down to actually printing the object out you don't have any problems and just press print.