Tolerances and Fits in 3D Printing: How to Get It Right with Your Bambu Lab X1C

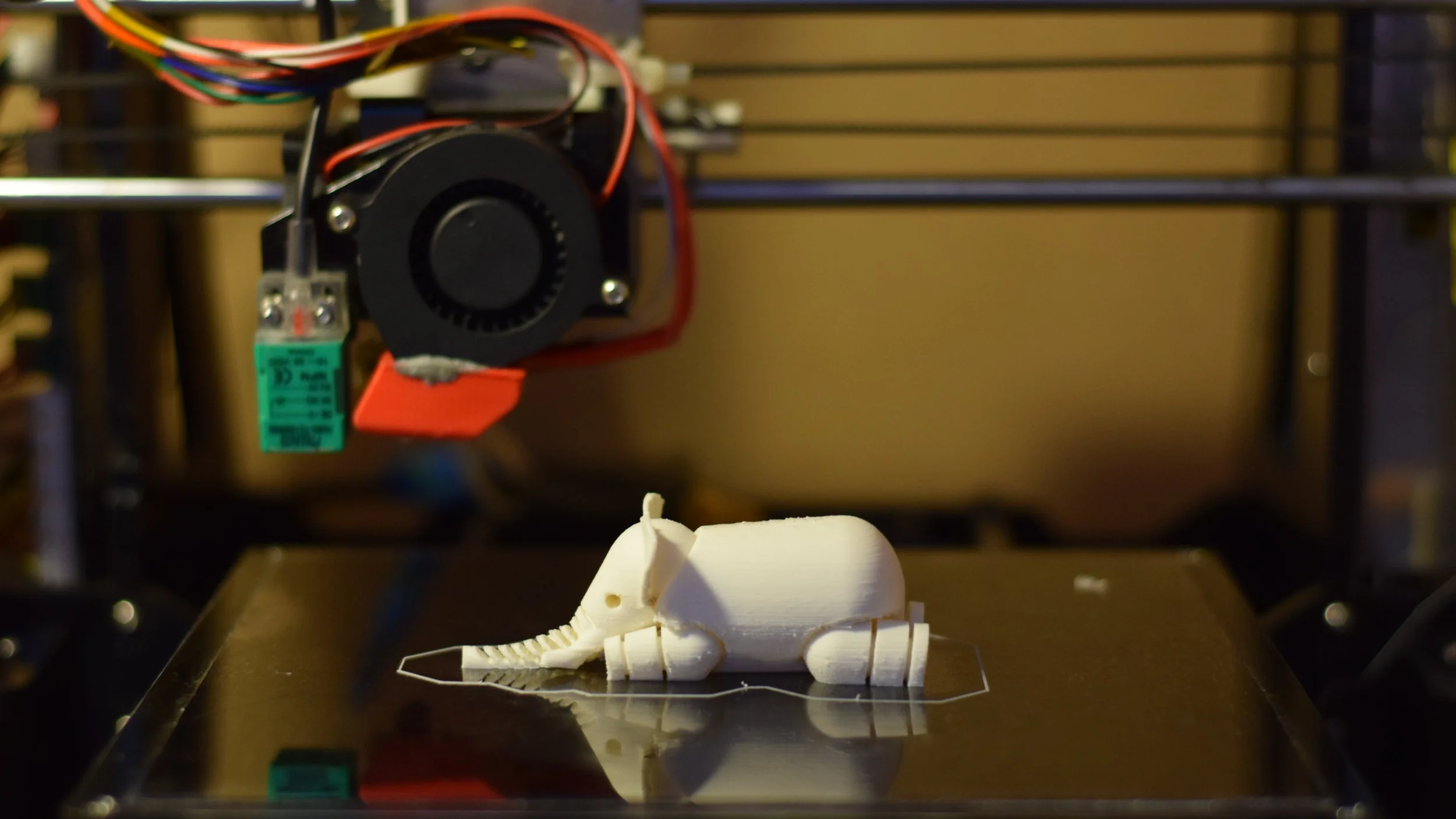

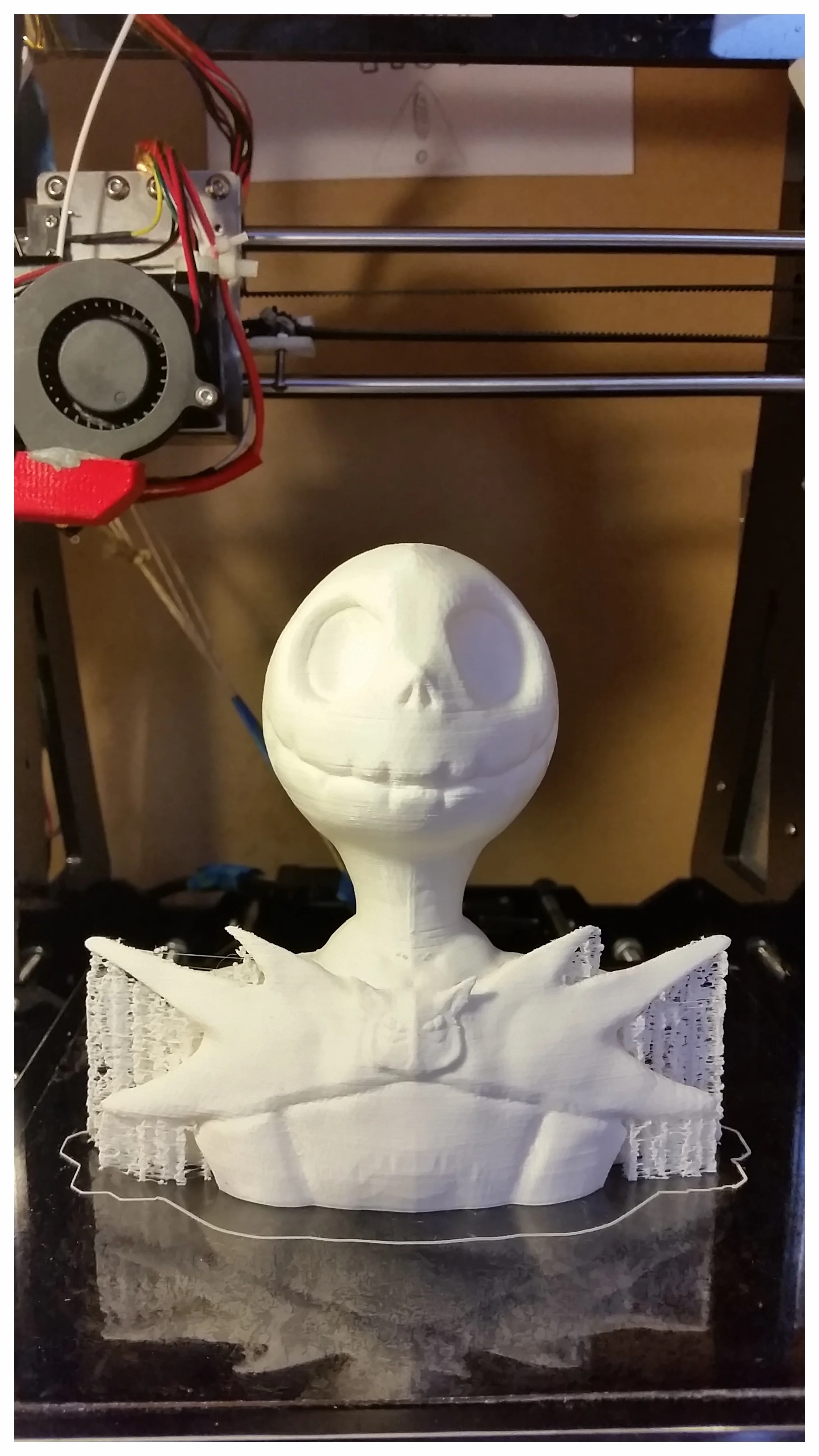

/If you’re into 3D printing, you’ve probably realized that getting parts to fit together perfectly isn’t as easy as it seems. Whether you’re making a snap-fit case or a functional prototype, understanding tolerances and fits can make or break your design. With the Bambu Lab X1C, you’ve got a powerhouse printer at your disposal, but to truly nail your projects, you need to get familiar with designing for tolerances. Let’s dive into what that means and how you can get your parts fitting just right.

What Are Tolerances and Fits Anyway?

In simple terms, tolerances are the leeway you give to your dimensions—the tiny allowances that let things fit together even when your printer isn’t 100% precise. Fits describe how two parts interact, whether they slide smoothly, press together tightly, or somewhere in between. Here’s a quick rundown:

Clearance Fit: There’s always a little space between parts, perfect for things that need to move freely.

Interference Fit: Parts are slightly larger than the hole or space they’re going into, which means you’ll need to force them together. Think press-fit connections.

Transition Fit: This is a sweet spot between the two—parts fit snugly but not too tight.

Getting these right in your design can save you from the headache of sanding, adjusting, or, worse, reprinting entire parts.

Common Challenges in 3D Printing Tolerances

3D printing isn’t perfect, and a few common issues can throw your tolerances off. With the Bambu Lab X1C, you’re already ahead in terms of precision, but there are still some quirks to watch out for:

Shrinkage and Warping: Plastics like ABS and PETG shrink as they cool, which can mess with your dimensions.

Print Orientation: How you place your part on the print bed can impact accuracy, especially for things like holes and overhangs.

Layer Height and Resolution: Smaller layer heights give you better detail and accuracy but can significantly increase print times.

Designing for Perfect Fits

Here’s how to design parts with the right tolerances:

Start with Standard Tolerances: For clearance fits, start with a 0.2-0.3 mm gap. For interference fits, try a slight overlap of 0.1-0.15 mm. It’s a good rule of thumb, but adjust based on your specific material and printer quirks.

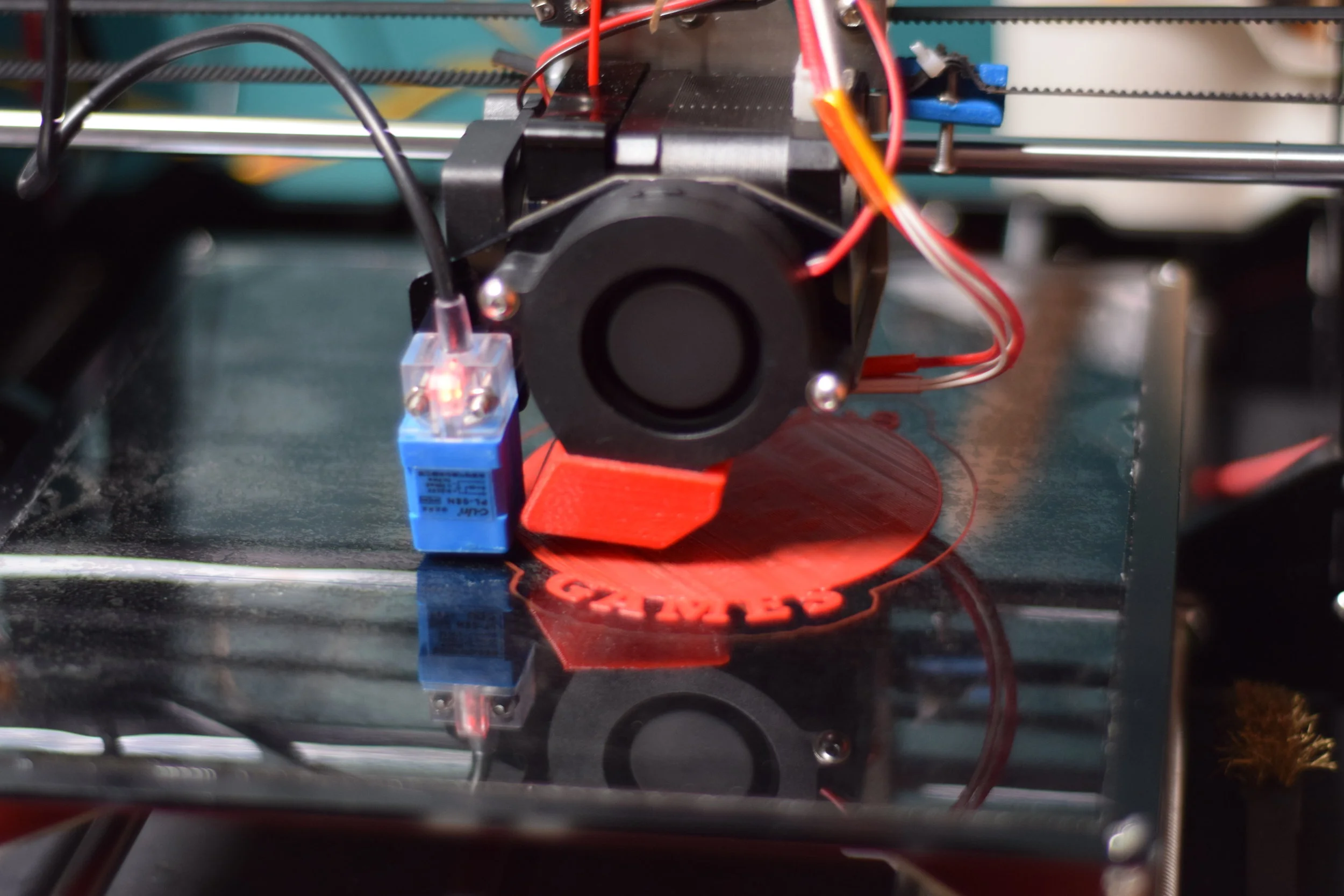

Test, Test, Test: Use small calibration models to dial in the tolerances specific to your Bambu Lab X1C. It’s better to tweak a tiny test print than waste time and filament on a full-scale project.

Mind the Print Orientation: Holes often print smaller when oriented vertically due to how the printer lays down material. If precise holes are critical, consider orienting your print differently or slightly enlarging the hole in your design.

Account for Material Behavior: Each material behaves differently—PLA is pretty stable, but ABS can shrink a lot. Use the material-specific profiles on the X1C to help manage these variances.

Don’t Skip Post-Processing: Sometimes, the best fit is achieved after a little work. Light sanding, reaming holes, or a quick heat gun adjustment can make all the difference.

Using the Bambu Lab X1C for Better Precision

The Bambu Lab X1C is packed with features that help you get those fits just right:

Auto Calibration: This feature helps ensure your first layers are perfect, setting a solid foundation for accurate prints.

High-Resolution Printing: Dial in those finer details without sacrificing too much time.

Material Profiles: Use these to adjust settings automatically based on the filament you’re using, helping to mitigate issues like shrinkage and warping.

Why This Matters: Beyond Just Fits

Getting your tolerances and fits right isn’t just about making your parts work—it’s about efficiency, less waste, and smarter manufacturing. When your prints fit the first time, you’re reducing the need for reprints and post-processing, saving both time and material. Plus, it’s all part of what makes 3D printing such a sustainable option: less waste, more precision, and the ability to fine-tune designs on the fly.

Wrap-Up: Keep Experimenting and Improving

Designing for tolerances and fits in 3D printing is part art, part science. It takes some trial and error, but with the right approach and the capabilities of your Bambu Lab X1C, you can turn out parts that fit together perfectly straight off the print bed. So keep experimenting, tweak those settings, and enjoy the process of perfecting your prints. Happy printing!